Application of silicone adhesive double-sided tape with adhesive/primer methods.

Jan 03,2023

The materials for single-sided tape and the release liner materials for double-sided tape must undergo a release coating treatment. The release coating ensures that the tape can lay flat smoothly during use. This is particularly important in automated applications where the tape is applied quickly. The release coating can provide different types of release levels to adjust the tape's difficulty according to customer requirements.

Release liner materials for double-sided tape

To ensure the tape can be used successfully and according to standards, anti-adhesion liner materials must be used. The materials can be plastic film or special paper:

Glass stickers: Standard solutions

PE coated whiteboard paper: Waterproof

MOPP plastic film: Mainly used for die-cutting into sheets and automated processes

PE plastic film: Mainly used for foam tape

PET plastic film: Mainly used for high-precision die-cutting in the electronics industry

Detailed introduction to the application of silicone stickers with 3M double-sided tape using adhesive/primer methods

Why silicone double-sided tape is not stable and must use adhesive/primer; because silicone is an amorphous chemical substance, a type of enzyme-absorbing material, classified as a plastic material, directly using double-sided tape for bonding cannot achieve ideal compressive strength, so it must be processed with silicone double-sided tape adhesive primer to achieve the melting effect of double-sided tape and silicone. Silicone double-sided tape primer is widely used in home and industrial applications, commonly used for silicone cushion decorations, silicone skins with large-scale double-sided tape, etc.

Clean the surface of the silicone (silicon) rubber products to be bonded of oil stains, water, residues, etc.

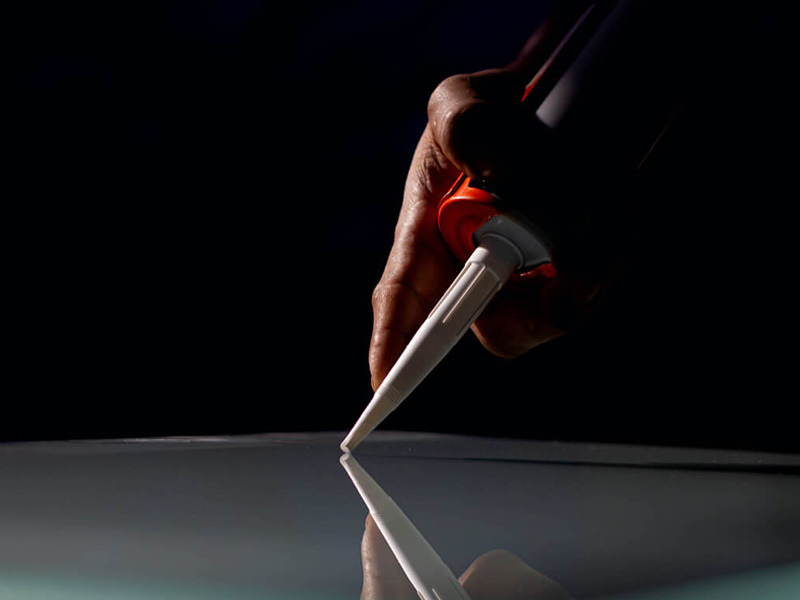

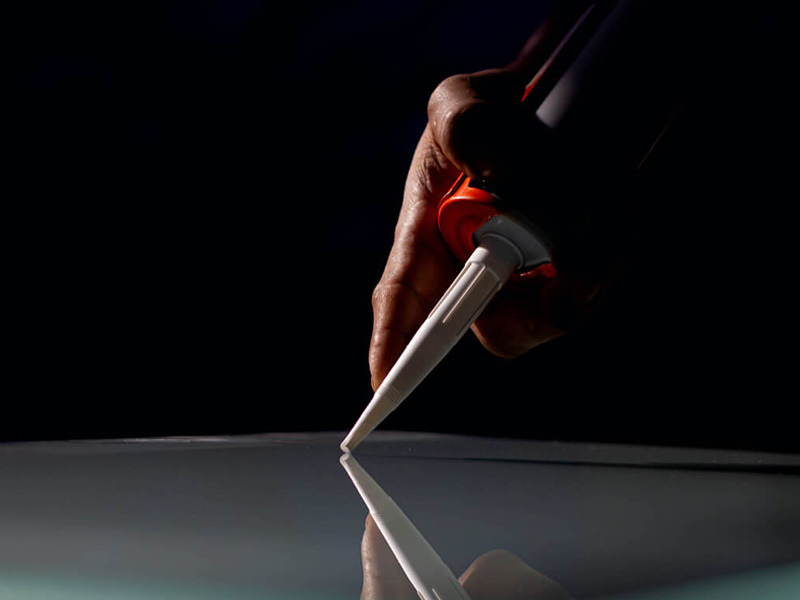

Apply G-777 giant arrow silicone adhesive modifier to the bonding surface of the silicone (silicon) product, generally applying one to two coats, and let it dry in a room temperature environment for 2-10 minutes.

3. Bond 3M double-sided tape or other polyurethane resin paper to the silicone (silicon) product that has been coated with G-777 silicone adhesive modifier, applying moderate pressure to ensure contact area.

4. After about 2 hours, it can be bonded into one piece, and the compressive strength will reach the melting effect after 24 hours.

Common issues

Before applying the primer, ensure that the silicone to be bonded is free of oil stains and dust.

The primer is a volatile adhesive and should be operated in a well-ventilated environment.

Due to differences in materials and double-sided tape, variations in bonding effects may occur. Please conduct bonding tests when using different materials and tape.

This product contains flammable organic solvents; please avoid open flames and heat sources during use and storage, and ensure good ventilation; store in an environment inaccessible to children. Thank you for reading, and I hope my sharing is helpful to you.

Previous article